ABOUT US Something About

DL Valve Pvt. Ltd.

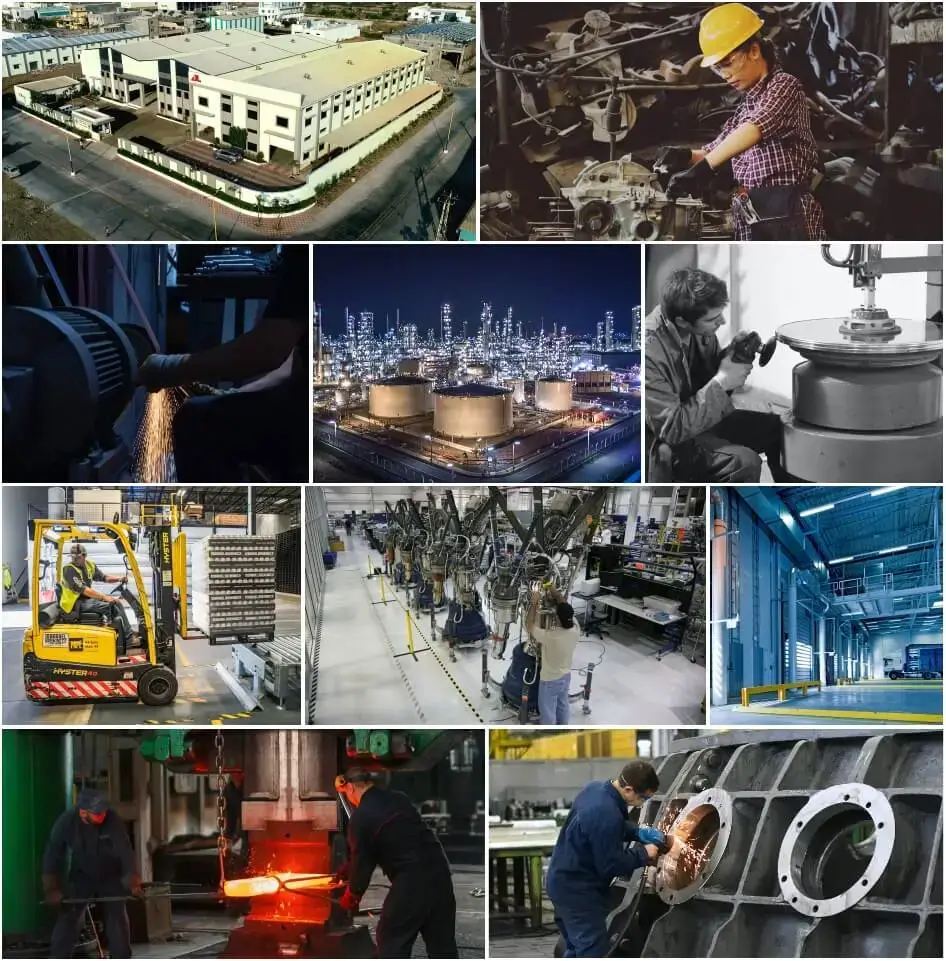

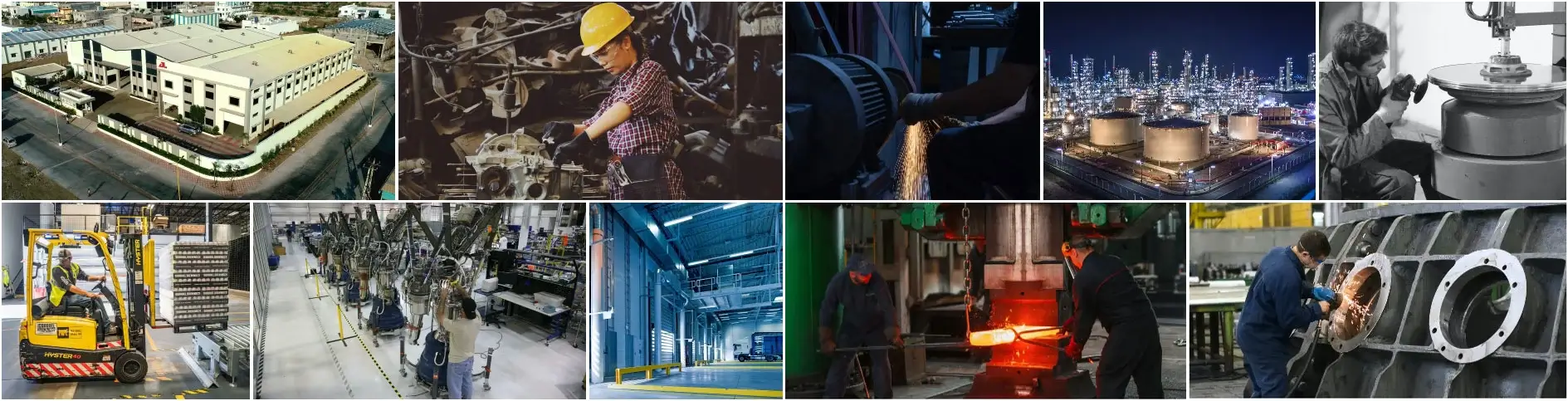

About to be a decade of experience in valve manufacturing and supply, DL Valve Pvt. Ltd. established with the aim of fulfilling the rising demand for quality valves in the year 2014.

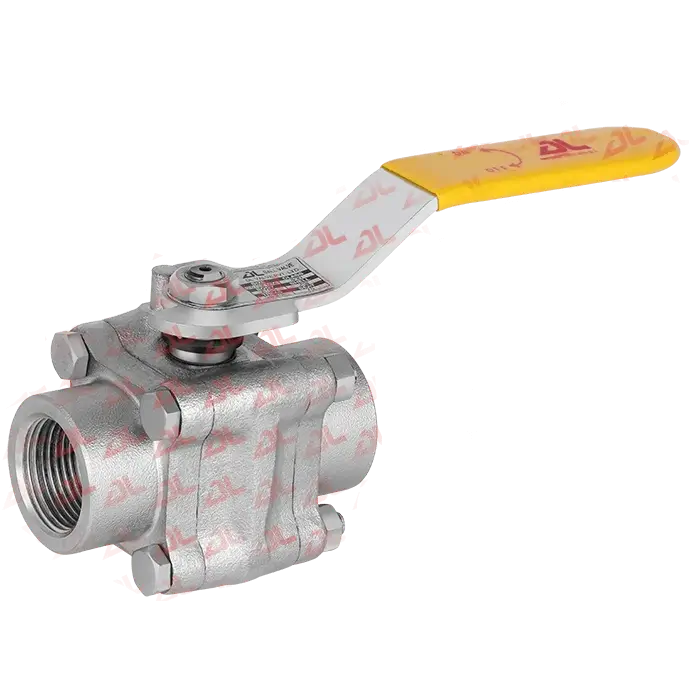

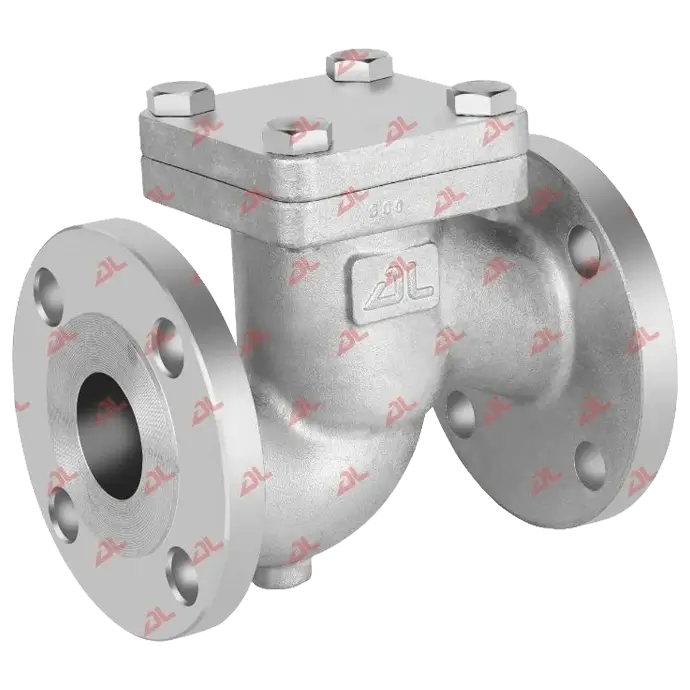

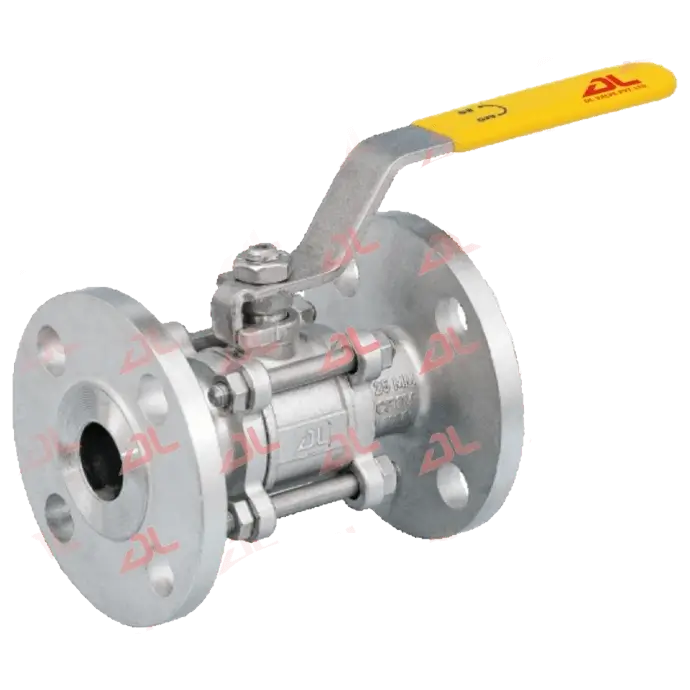

We are pleased to introduce DL Valve Pvt. Ltd. as a leading manufacturer of Gate, Globe, Check and Ball Valves. DL Valve Pvt. Ltd. has a single location for its optimized facility with the advanced manufacturing process. This gives us an advanced edge and provides us opportunities to supply quality valves to the market.

Know More About

Industries Industries

We Served

-

Nuclear Power

Plant -

Oil & Gas

Refinery -

Paper

Industry -

Chemical &

Petrochemical

Engineering -

Marine

Offshore -

Nuclear Power

Plant